Artificial Intelligence in Semiconductor R&D: A Comparative Study of China and Taiwan

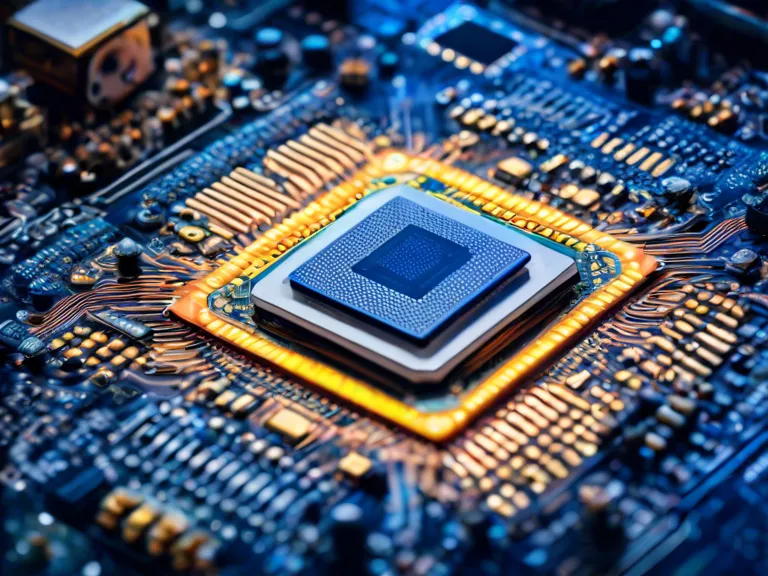

In recent years, the field of artificial intelligence (AI) has been making significant advancements in various industries, including semiconductor research and development (R&D). China and Taiwan are two countries that are at the forefront of semiconductor manufacturing, and their approaches to incorporating AI into R&D processes can provide valuable insights for the global tech industry.

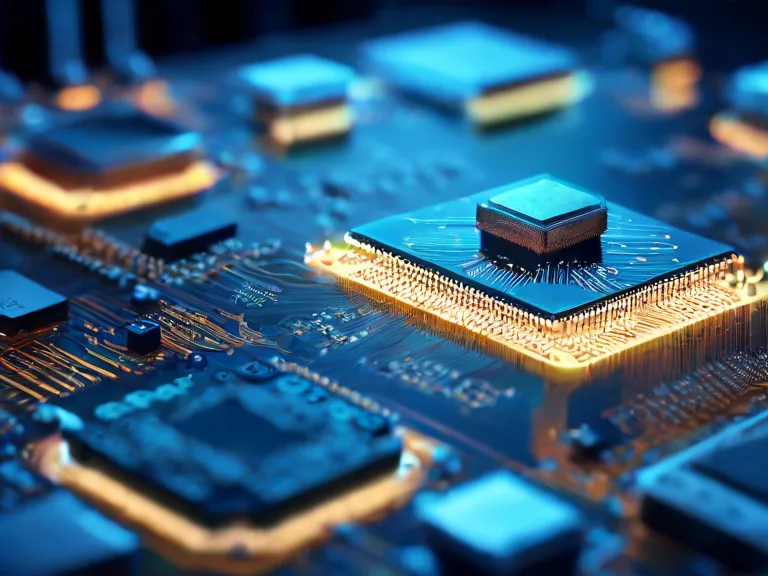

China, with its massive government support and investments in AI, has been actively integrating machine learning algorithms into its semiconductor R&D. From optimizing chip designs to improving production processes, AI technologies have enabled Chinese semiconductor companies to boost efficiency and innovation. In contrast, Taiwan, known for its semiconductor foundries and design capabilities, has been focusing on utilizing AI for yield improvement and defect detection in chip manufacturing.

Both countries have their strengths and weaknesses when it comes to AI in semiconductor R&D. China's vast data resources and government-backed initiatives give it a competitive edge in AI adoption, while Taiwan's established semiconductor ecosystem and expertise in chip design provide a solid foundation for AI integration. However, both countries face challenges such as talent shortages in AI and data privacy concerns that need to be addressed to fully leverage the potential of AI in semiconductor R&D.

By comparing the approaches taken by China and Taiwan in incorporating AI into semiconductor R&D, we can gain valuable insights into the best practices and strategies for maximizing the benefits of AI technologies in the semiconductor industry. As AI continues to evolve and shape the future of semiconductor manufacturing, understanding the unique perspectives and experiences of different countries can help companies stay ahead of the curve and drive innovation in this fast-paced industry.